Introduction

I like to think of myself as a seasoned shopper. I have been able to test my skills at some of the most notable stores in the world, from the biggest mall in America to designer flagship stores in Paris, but some of the best shopping experiences I’ve had have been at small businesses.

Small retailers don’t need elaborate experiential store models to succeed—but instead, they can benefit from helpful customer service, an adequate range of products, and visually appealing layouts. All of these factors (and more) can be tied back to effective inventory management, which is arguably the most important step in a small retailer’s supply chain due to its all-encompassing nature.

Why is Inventory Management Important?

It is important to get a firm grip on inventory management because of its use to both customers as well as employees. An effectively managed inventory allows customers to roam your store with ease and locate items they are looking for. It provides similar benefits for employees, along with aiding in accurate record keeping and avoiding over or understocking your store, which may help with both finances and daily store operations.

However, having the constraints of a small retail space may pose challenges for your inventory management. While larger retailers have the option to spread out inventory, a small retail space may limit your ability to track information regarding your merchandise. Instead of guessing how to combat this issue, I’ve compiled a list of the 7 best practices to manage your small business’ inventory.

Here’s a look at the topics we’ll cover in this article:

- Create SKU system

- Engage in Trend Forecasting

- Strategically Arrange Store Displays

- Run Promotions on Excess Stock

- Track Inventory Levels Regularly

- Invest in Inventory Management Software

- Consider Warehouse Options

- Conclusions

1. Create SKU System

An SKU, or Stock Keeping Unit, is a label given to merchandise in order to track inventory levels. SKUs are alphanumeric labels that can be found on bar codes or product labels of merchandise to make them easily identifiable. SKU codes can be computer-generated or made by hand, but there are a few things to consider when creating an SKU label:

- SKU codes can be any length. A key to creating an SKU is to find an appropriate length—long enough to contain specific, identifiable information, but not too long that the information gets lost in a jumble of letters and numbers.

- Start the code with a top-level identifier. This will likely be the category that the product falls under. A clothing retailer’s first characters of a SKU number might be 10 for jeans, 20 for shirts, 30 for outerwear, 40 for shoes and so on. Or, it could look like JE for jeans, SH for shirts, OU for outerwear, and SO for shirts. This system is up to the retailer’s discretion.

- Use the middle part of the code to get into more specific characteristics of the products at hand. For the category of jeans, numbers can be assigned to identify certain styles, colors, or sizes. When you read the SKU, you should be able to identify if the product is a pair of size 6 black flared jeans.

- Finally, finish your product label with a sequential number in order to track each specific piece of merchandise. So, for every pair of size 6 black flared jeans in your store’s inventory, 01, 02, and so on may be added to the end of its SKU number to understand which pairs are in stock.

SKU’s are especially helpful when programming a Point of Sale (POS) system or other inventory tracking software, which we will discuss in upcoming steps.

2. Engage in Trend Forecasting

As we’ve briefly discussed already, one of the major goals of inventory management for a small retailer is to ensure that there is enough product to meet consumer demand without having an overstock or understock of merchandise. A way to ensure adequate levels of inventory stock is to trend forecast.

Trend forecasting is a great way to predict sales figures based on historical transaction data. By doing so, your company can predict how much stock to order for the next season and understand how much merchandise to keep in store at all times. This process can also assist with Just In Time Inventory (JIT) management, in which a company orders materials and merchandise from a supplier on an as-needed schedule, reducing inventory costs and preventing over-crowding in store.

Plus, fashion trend forecasting allows you to understand what your consumers will be looking for in the next season and give you an advantage when drawing shoppers into your store. It can also help you identify gaps in your merchandise line and know what products to source in order to fill empty spaces.

Methods to trend forecast include purchasing subscriptions to forecasting platforms, following the same platforms on social media, or even conducting your own market research.

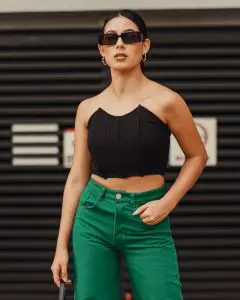

3. Strategically Arrange Store Display

Instead of tracking what merchandise is coming into your store, another way to engage in inventory management is to control how much and what merchandise is leaving your store. A way to achieve this strategy is to arrange your store layout and displays to push old inventory out to customers.

If you are looking for a way to get rid of excess inventory of merchandise from past seasons, arrange mannequins or product displays that assimilate the old inventory with new products. This way, older merchandise can still be seen as trendy and desirable to consumers. (Bonus: Displaying products as whole outfits will help customers see that they need all of the items in the arrangement, selling both newer and older merchandise!)

Pushing this older merchandise is also known as a First In, First Out model, or FIFO. This is the idea that merchandise should be sold in the order your company receives it, which is especially relevant for perishable goods.

In the case that you are displaying older clothing merchandise in the front of the store to follow a FIFO method, customers will inevitably have to travel to the back of the store to shop for new styles. This means that shoppers are forced to look at the older merchandise on their way to the newer products, making it more likely that they will pick up some of the past styles on the way.

4. Run Promotions on Excess Stock

Another way to sell control your inventory stock is to run promotions on excess merchandise. A few common ways to push older merchandise include putting a sale rack outside of your store to draw consumers inside, run BOGO sales, offer additional percentages off of already on sale merchandise, or hosting end of season sales.

While running sales promotions on older merchandise can be very effective, it is important to use these tactics strategically on last call products. If used too frequently, consumers may begin to view your store as somewhere they shop strictly for sale items, and rarely purchase full priced items.

5. Track Inventory Levels Regularly

There are several ways to track inventory levels, but they all trace back to SKU’s. After creating your SKU system, you can use everyday resources to track stock levels in order to improve your customer service, regulate your finances, and prevent inventory shrinkage.

It may be beneficial for your growing company to hire a stock controller whose duties are specific to operations. At the beginning of each day, they can take note of any SKU’s present in the store. During store hours, they can oversee what merchandise is sold, in order to not only keep up with inventory levels but note sales trends as well. After each day, they re-check the SKUs left in the store while referencing the records for that day.

By hiring a stock controller and following this process in-store, small retailers can reduce the amount of money lost on stolen or unaccounted for items, and also record data on low-turn and high-turn products.

6. Invest in Inventory Management Software

An easier and more efficient way to keep track of inventory is to invest in cloud-computing software. This kind of software can organize SKU codes and act as a POS system instead of having to manually input information into an Excel sheet. POS software can multitask at the click of a button—it can provide accurate pricing at the time of sales, check the stock levels of merchandise through SKU records (even among store locations, if applicable), keep track of vendors in order to quickly reorder products, and record raw data on customer transactions and convert to useful inventory management.

Some of the available software options include

- Square

- Oracle NetSuite

- Netstock

- Flowtrac

among many others. These information system options often run for less than $100 a month and provide advanced features and in-depth reports on your inventory management that may save you from losing hundreds of dollars due to human error.

7. Consider Warehouse Options

If your small business is growing and inventory seems to be overflowing in your storage room, it may be time to consider using warehouse storage. Investing in warehouse space will allow you to only keep essential stock in store and hold onto next season or last season’s merchandise in a non-cluttered way. This may provide value to your small business by improving customer experience, as well as creating an efficient space to tag and label inventory.

This extra space will also allow you to hold more safety stock. Working hand-in-hand with a POS software, you can set up low-stock alerts that will give you notice as to when merchandise should be restocked in store.

If investing in a warehouse is not right for your small business, considering drop-shipping may be. Especially if you are running an e-commerce business, drop-shipping is another tactic to ensure JIT inventory management by skipping many middle elements of your supply chain and providing direct to consumer service.

8. Conclusions

Inventory management is important for many reasons, such as improving customer experience, preventing over and understocking, and staying on top of financial obligations. In this article, we discussed 7 examples of how small businesses can effectively practice inventory management. First and foremost, they can create a Stock Keeping Unit system to label their merchandise with an alphanumeric code. This makes every piece of merchandise easily identifiable for employees, and in some cases, consumers. Second, we discussed the benefits that trend and sales forecasting can have on inventory management. Forecasting can aid with Just in Time inventory tracking. Third, businesses can strategically arrange store displays to help get rid of older merchandise while selling new merchandise as well. Fourth, small retailers can run promotions on low stock they do not plan on replenishing. Fifth, companies can hire a stock controller to manually track inventory levels each day in order to prevent inventory shrinkage costs. Sixth, retailers can consider investing in a cloud-based inventory management software to work in tandem with its SKU system. Labeling products and programming them into a POS system automatically generates inventory reports and accurate information. Seventh, we finally discussed the option of investing in warehouse space to organize inventory and have more space to label and tag products.

The goal of any of these practices is simplify both daily and long-term business operations in order to create more efficient business processes that will benefit the employees and customers of small retailers.